Status Blogs

StanceWorks Features Inside the American Made Status Racing

“Made in America” is a statement few companies in the automotive aftermarket can make. When it comes to the seat industry, that list is even fewer. Status Racing, one of the leaders in top-tier racing seats, can proudly make that claim, and as expected, it is a statement that holds its value. Status takes pride in representing the culmination of superior technology and aerospace materials, and that is why we’re sharing with you.

Rob and Dan, new partners of Status Racing, have had their head in the automotive scene for quite some time; more than a decade. In fact, there’s a good chance you’re familiar with them. In 2001, Rob and Dan started a company called Vivid Racing with $500 in their pockets and a $1500 loan. Today, Vivid has 30 employees and is a $10,000,000-per-year company. So when news came about that Status needed a well-founded partner, the pair knew they were the right fit. Rob and Dan’s success in online sales and marketing gave them the confidence to jump in the driver’s seat. They’re now entering 2012 stronger than ever.

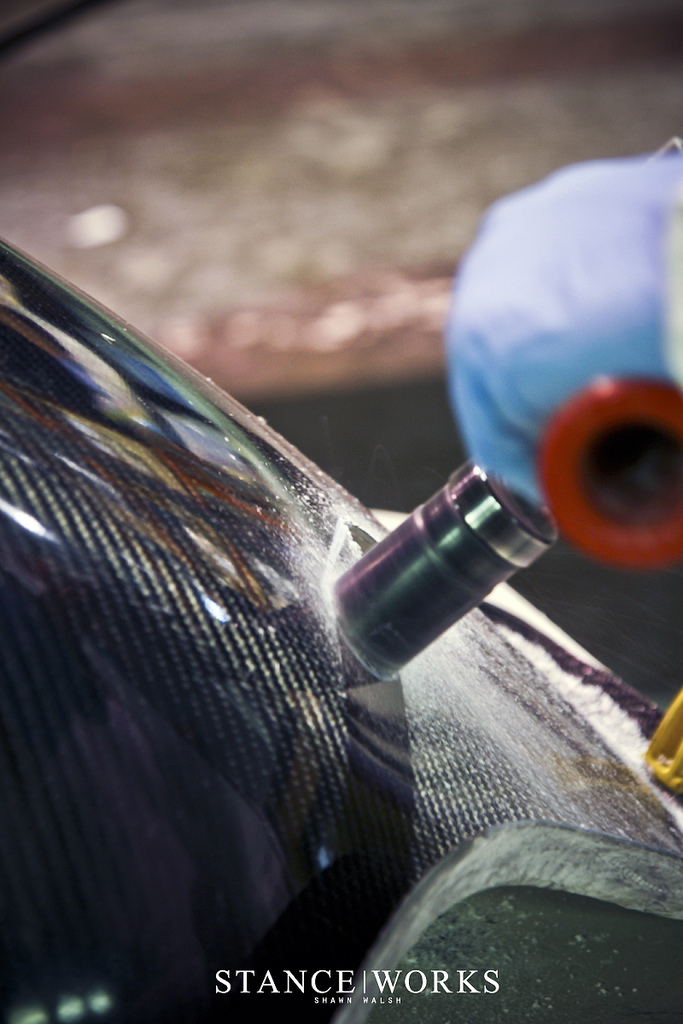

Much of the construction of a Status seat is proprietary information, aka “Top Secret”, but Dan spilled the gist of it as simply as he could. “The basics are exactly what you see. A mold is made to the specs we design. Material is laid in the mold and then coated. Once the mold is ready to be seperated, the seat shell is visible and we trim out the excess. From here we add the padding, bracket hardware, and put on the custom Icon or standard seat jacket. It’s then ready to ship!”

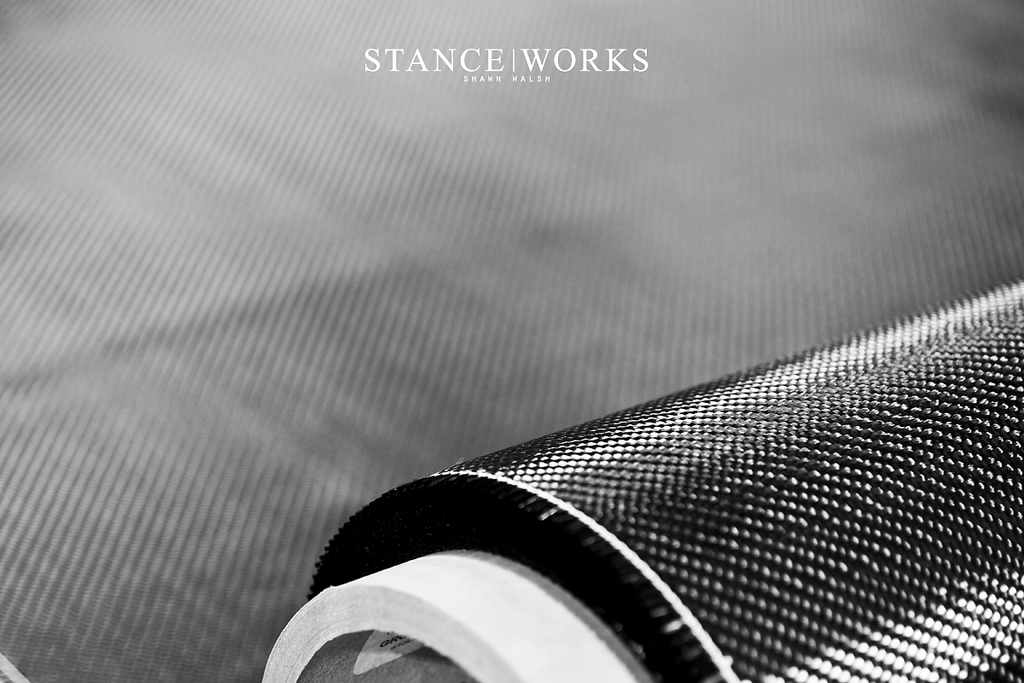

If you’re unfamiliar with Status, or with top-of-the-line seats as a whole, you’ll be interested in what makes up their construction. The upper-level Status seats are made of, as seen here, carbon-fiber, or if your pockets are even deeper, carbon-kevlar. Carbon-kevlar, the lightest composite Status offers, is the pinnacle of light weight seat production. Its unique golden-yellow appearance is a dead giveaway.

In keeping with the American tradition of unparalleled quality, Dan tells me how seriously Status takes quality control. “We hold our seats to extreme quality control. We make sure that the presentation of the seat from the packaging to the final product keeps people excited and confident. Everything down to the finest stitch has to be perfect. If there are any flaws in the carbon weave, it is not used or sold later as a blem. Since seats are being made 1 at a time start to finish, it allows for serious control over the final product outcome.”

But if Status’s manufacturing and quality weren’t enough to separate them from the rest of the industry, perhaps their Icon Series is. The idea behind the Icon Series is the ability to custom tailor a seat to fit the aesthetics of any vehicle. The entire skin of the seat is “customizable”, from the fabric type and color, to the color of the stitching, seat inserts, and logos. And as for what’s next for Status? Rumor has it reclinables and even some larger seat sizes.

Status is growing quickly, and we’re excited to share their story. An American company with American ideals, it’s what we’re all about. Dan put it perfectly: “We dont want to be a replacement for other seat companies in motorsports, we want to be the seat choice for enthusiast and racers because of the uniqueness.”